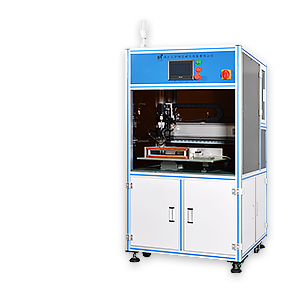

Small IF inverter spot welding without adding any solder, high efficiency, low cost. Easy to automate and so on. IF inverter spot welding using high-performance pneumatic components, the main shaft and the guide shaft are chrome round, the pressure transmitted is flexible and reliable, no phantom generated. Welding transformer secondary internal forced cooling, and the use of optimized design, high permeability materials, low load loss, power output, stable, long life.

Welding controller adopts digital integrated control system or microcomputer resistance controller control (optional), with pressure time, welding time, delay, rest, welding current and other parameters, with dual-pedal, double pulse, dual current Control functions, as well as SCR temperature monitoring. Various types of welding controller to meet different functions, can achieve a multi-purpose machine. Welding primary circuit using bidirectional water-cooled SCR control, to ensure current output balanced and reliable.

News

- Brief description of the main advantages of the welder which

- Spot welding machine daily operation and maintenance

- Exchange the advantages and disadvantages of automatic spot welder

- Small frequency inverter spot welder with easy automation features

- IF frequency welder pressure refers to what

- Automatic spot welding main components and features

Product

-

BT-100V-20C-200F BATTERY PACK PERFORMANCE TESTER

BT-100V-20C-200F BATTERY PACK PERFORMANCE TESTER

2021-04-09

-

BT-2113B ENERGY-STORAGE POWER BATTERY PACK SEMI AUTOMATIC PRODUCTION LINE

BT-2113B ENERGY-STORAGE POWER BATTERY PACK SEMI AUTOMATIC PRODUCTION LINE

2021-04-09

-

BT-450 INSULATING PAPER PASTING MACHINE

BT-450 INSULATING PAPER PASTING MACHINE

2021-04-09

-

BT-850B-10000A TRANSISTOR DOUBLE SIDED AUTOMATIC SPOT WELDING MACHINE

BT-850B-10000A TRANSISTOR DOUBLE SIDED AUTOMATIC SPOT WELDING MACHINE

2021-04-02

-

BT-960-960XZ Single Side Automatic Spot Welder

BT-960-960XZ Single Side Automatic Spot Welder

2021-04-01

Telephone:0755-81710691

Fax:

Mailbox:z609665418@163.com

Address:221 Fukang Industrial Park, Guanlan Renmin Road, Longhua District, Shenzhen

粤ICP备14041565号